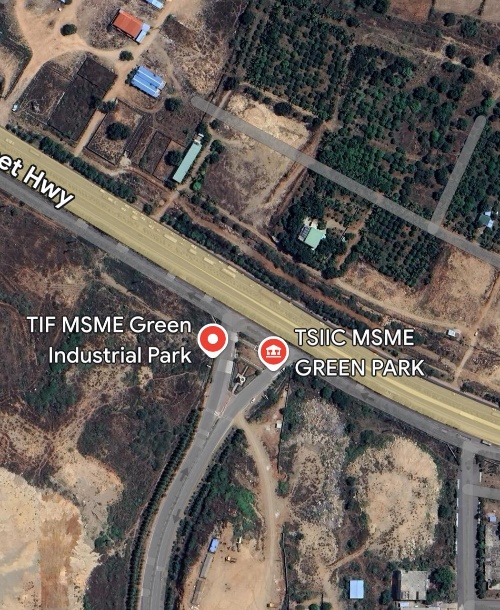

Event Name : Industrial visit to TIF-MSME Green Industrial Park

Date of Visit: 25th September 2024

Venue: TIF-MSME Green Industrial Park, Dandumalkapur, Yadadri Bhuvanagiri District

Inaugurated by: Telangana IT & Industries Minister KT Rama Rao

Objectives:

Learning Outcomes:

Industrial Park Overview:

The TIF-MSME Green Industrial Park is a government-initiated project that supports small and medium enterprises (SMEs) by providing them with world-class infrastructure and access to key resources. The Park spans over 543 acres, housing 559 industrial units, with more than 200 units currently under construction and expected to commence operations by June 2025. Around 30 units have already started production, demonstrating the rapid pace of development in this zone.

Developed with a budget of ₹236 crores, the park offers robust infrastructure, including water supply, power, roads, drainage systems, and other essential utilities. An integrated township spread across 194 acres is also planned to promote a ‘walk-to-work' culture, further enhancing productivity and convenience for employees.

For the students, this visit offered a unique glimpse into how such a large-scale industrial project is planned, financed, and executed. They observed how regulatory oversight, sustainable practices, and financial decisions play a vital role in supporting SMEs. These learnings were especially relevant in understanding India’s growing industrial landscape, government incentives for MSMEs, and the importance of ethical finance in sustaining industrial growth.

(Caption for first image)

(Caption for second image)

Company Visits and Insights:

The group visited three key industries within the park: Sai Deepa Rock Drilling Tools Pvt. Ltd., VEC Chocolate Machines Pvt. Ltd., and Sodahub Industrial Automation. Each visit provided specific insights into different aspects of business operations, finance, and corporate governance.

(SCMS Batch 23-27 Industrial Visit)

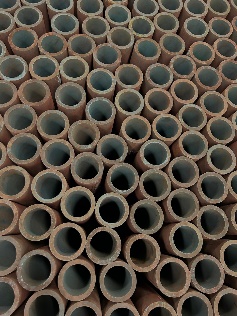

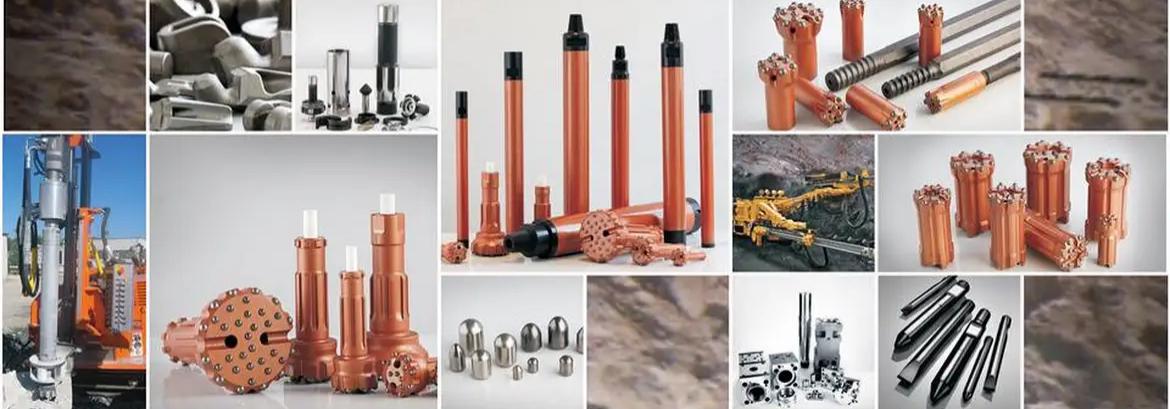

1. Sai Deepa Rock Drilling Tools Pvt. Ltd.

Industry Focus: Sai Deepa is a leading manufacturer of rock drilling and water well drilling equipment, providing tools that are essential in the mining, construction, and water resource sectors.

- Financial Management in Capital-Intensive Industries: The students learned how the production of high-cost, specialized machinery requires substantial financial investments and cash flow management. The company representatives explained how they manage costs, balance procurement and production, and finance large-scale projects, giving students a clear understanding of financial logistics.

- Corporate Governance and Risk Management: In addition to financial planning, students discussed the importance of adhering to ethical practices in large industries where safety, environmental concerns, and regulatory compliance are critical.

- Sustainability: Sai Deepa also demonstrated the use of sustainable practices, such as using energy-efficient technologies in the manufacturing process, which aligns with global goals of reducing carbon footprints in industrial production.

(Company Introduction)

(Company Performance Overview)

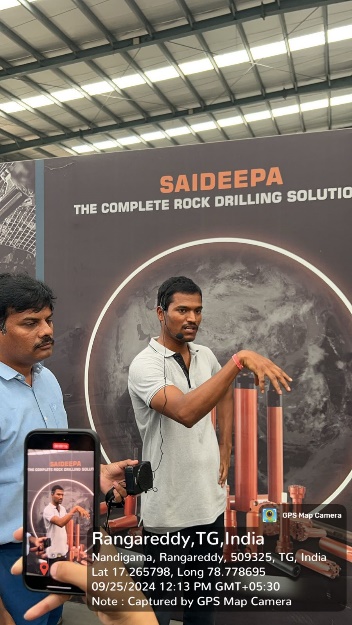

(Employees Explaining the Process)

(Students Asking Questions)

(An Insight into Factory Operations)

(A token of appreciation from SCMS-H)

The employees at Sai Deepa demonstrated a strong commitment to excellence and were eager to share their expertise, making complex concepts in tool manufacturing easy to understand. Their focus on quality control and innovation was evident throughout our visit, and the collaborative atmosphere fostered a genuine sense of community. We appreciated their patience in addressing our questions and the hands-on demonstrations that enhanced our understanding of their processes. Sai Deepa’s dedication to continuous improvement and customer satisfaction truly sets them apart, and we are grateful for the insightful experience.

VEC Chocolate Machines Pvt. Ltd.

- Industry Focus: VEC Chocolate Machines specializes in manufacturing machines that are integral to the processing of chocolate in the confectionery industry, from mixing to moulding and packaging.

(A token of appreciation from SCMS-H)

The employees at Sai Deepa demonstrated a strong commitment to excellence and were eager to share their expertise, making complex concepts in tool manufacturing easy to understand. Their focus on quality control and innovation was evident throughout our visit, and the collaborative atmosphere fostered a genuine sense of community. We appreciated their patience in addressing our questions and the hands-on demonstrations that enhanced our understanding of their processes. Sai Deepa’s dedication to continuous improvement and customer satisfaction truly sets them apart, and we are grateful for the insightful experience.

VEC Chocolate Machines Pvt. Ltd.

- Industry Focus: VEC Chocolate Machines specializes in manufacturing machines that are integral to the processing of chocolate in the confectionery industry, from mixing to moulding and packaging.

(A token of appreciation from SCMS-H)

Students took away valuable lessons on balancing profitability with ethical operations, which are critical when managing a consumer-facing business.

(Chocolate machine manufacturing)

(Appreciation for VEC Chocolate Machines Pvt. Ltd. Employees’ Hospitality and Guidance)

Learning Outcomes:

- Operational Efficiency and Cost Control: In this industry, operational efficiency is paramount to maintaining competitive prices in a high-demand market. Students were introduced to how VEC utilizes modern machinery to optimize production and reduce costs. The focus was on how streamlined production reduces waste and increases profitability—lessons directly relevant to managing business operations in any sector.

- Inventory and Supply Chain Management: VEC’s representatives discussed how they manage their inventory to meet the dynamic demand in the food industry. This provided students with real-world examples of supply chain logistics and inventory financing, crucial for any business manager.

- Ethical Sourcing and Corporate Governance: VEC is committed to ethical sourcing, ensuring that their ingredients and materials are obtained through sustainable and responsible practices. The students reflected on how ethical practices in sourcing and production can influence a company’s brand value and customer trust, providing long-term benefits in both financial and reputational terms.

Sodahub Industrial Automation

- Industry Focus: Sodahub is involved in creating cutting-edge industrial automation solutions, helping various industries enhance their production efficiency through advanced technologies like robotics, AI, and IoT (Internet of Things).

(Soda machine manufacturing)

- Learning Outcomes:

- Investment in Technology: The company showcased how investing in automation technologies can provide long-term financial benefits by reducing labour costs, minimizing human error, and increasing production speed. The discussion covered the financial implications of adopting automation and the payback period, providing a case study on how capital investment in technology can drive profitability.

- Regulatory Compliance and Safety: Automation also brings challenges in ensuring compliance with industrial safety standards. Sodahub’s management emphasized the need for stringent regulatory compliance to protect workers and maintain operational integrity. This aspect taught students about the balance between innovation and regulation—a crucial lesson for any future manager in a tech-driven industry.

(A token of appreciation from SCMS-H)

(M.Gopal Rao, Director, TIF(Left), K.Sudhir Reddy, President, TIF (Right)

(Appreciation for the President of TIF and Managing Director of TIF Integrated Industrial Parks Pvt Ltd.)

Julla Srikanth, Manager

(Telangana Industrialists Welfare Federation (TIF) & TIF Integrated Industrial Parks Pvt Ltd)

IMPACT ON STUDENTS:

1. Practical Exposure to Industrial Operations:

For management students, theoretical knowledge is important, but experiencing real-world industrial processes brings learning to life. The visit to TIF-MSME Green Industrial Park allowed students to witness how complex industrial operations are planned and executed, from raw material procurement to final product delivery. By understanding the financial, operational, and regulatory aspects of these industries, students developed a more comprehensive understanding of business management.

2. Enhancing Critical Thinking and Problem-Solving:

Each industry presented its own unique challenges—be it managing large-scale financial investments, optimizing supply chain logistics, or ensuring compliance with safety regulations. Students were encouraged to ask questions and think critically about how they would tackle these challenges as future managers. This exercise in problem-solving fostered their analytical skills, which are crucial in making informed business decisions.

3. Learning Corporate Governance and Ethical Finance:

Throughout the visit, a recurring theme was the importance of ethical governance and transparent financial practices. Whether it was ensuring sustainable sourcing at VEC Chocolate Machines or complying with safety regulations at Sodahub, students were reminded of the importance of integrity in business. These lessons in corporate governance and ethics will be invaluable as they transition into leadership roles where they will need to uphold ethical standards while achieving business goals.

4. Hands-on Understanding of Financial Management:

The industrial visit provided practical insights into how companies manage their finances in capital-heavy industries. From financing machinery production at Sai Deepa to investing in automation at Sodahub, students could see the direct application of financial principles they study in the classroom. This practical exposure helps bridge the gap between academic learning and real-world financial management.

(Students Gaining Insights into Factory Operations)

ITINERARY:

- Travel: The group travelled to the industrial park using college-provided shuttle service, which allowed for comfortable travel and team bonding.

- First Stop (Sai Deepa Rock Drilling Tools): After a tour of the production site, the students broke for lunch at 2 PM.

- Second Stop (VEC Chocolate Machines): The visit continued with an engaging session on confectionery machinery, followed by a hands-on demonstration of their production technology.

- Final Stop (Sodahub Industrial Automation): The day concluded with an exciting tour of Sodahub’s automation solutions, which gave students a deep dive into the future of industrial operations.

Conclusion:

The industrial visit to TIF-MSME Green Industrial Park was an enriching and insightful experience for the students of Symbiosis Centre for Management Studies. Through this visit, they not only gained a practical understanding of industrial operations and financial management but also developed critical skills that will aid them in becoming better managers. The exposure to real-world challenges, corporate governance, and innovative technologies has equipped them with the tools necessary to navigate the complexities of today’s business environment.

This visit reinforced the idea that a successful business manager is not just someone who understands finance and operations but someone who can also navigate the ethical and regulatory landscapes while driving innovation and sustainability.